8:00 - 17:30

Monday to Saturday

Monday to Saturday

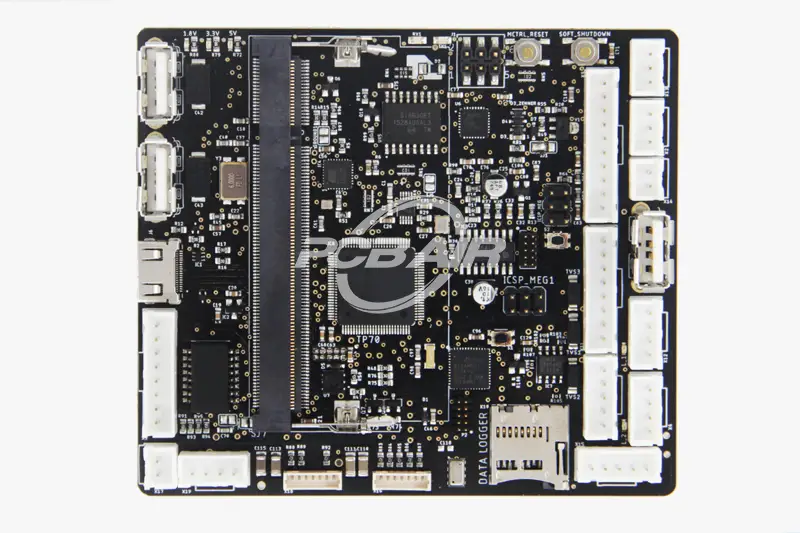

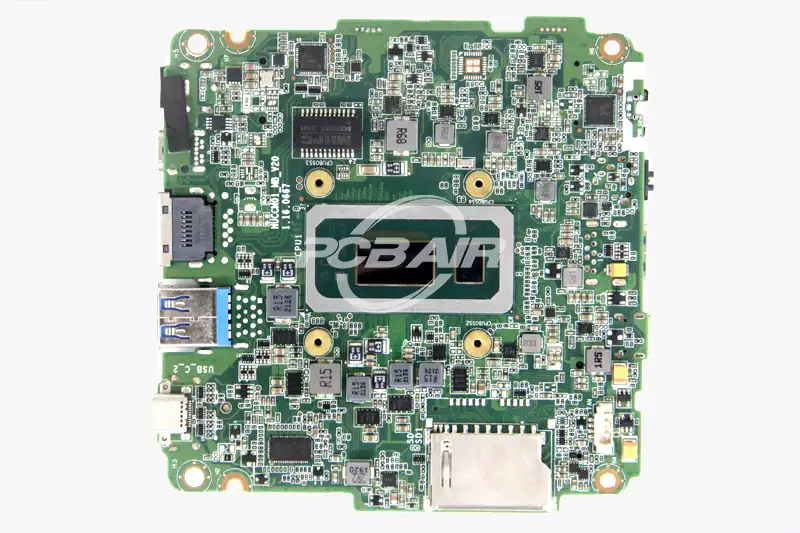

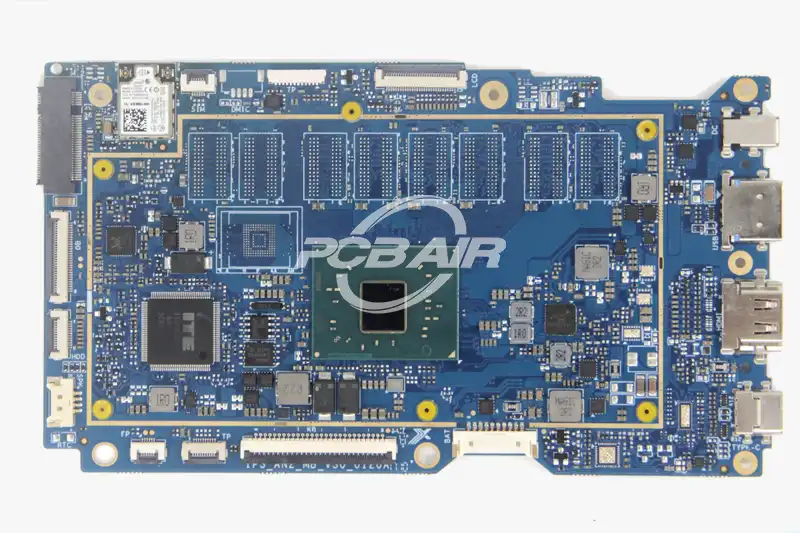

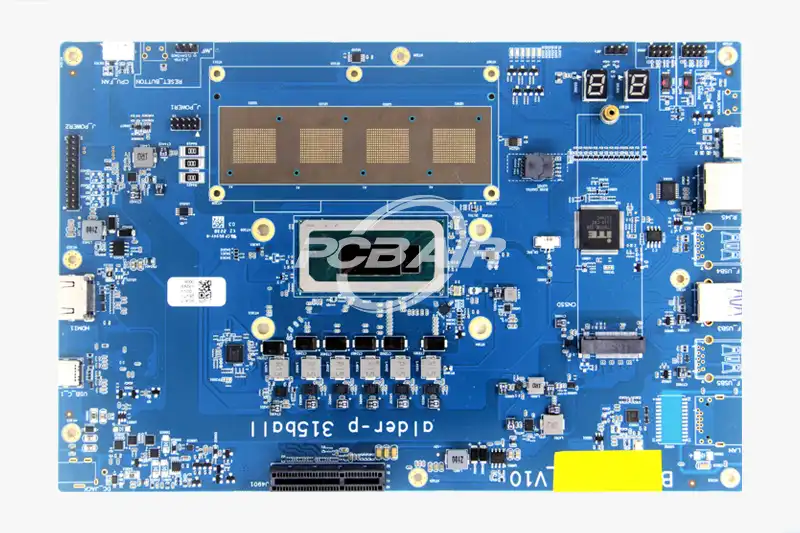

Our PCB Assembly Services

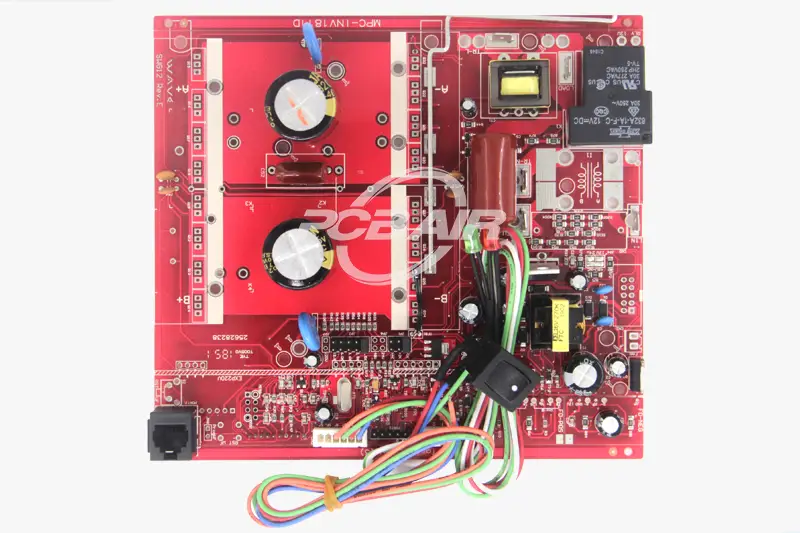

You can rely on us for printed circuit board assembly. We value quality, reliability, and on-time delivery. Whether your project needs custom, small-batch, large-volume, or lead-free PCB assembly, we can help. You’ll find our prices competitive for all your electronic manufacturing needs. Skip the hassle of sourcing parts and dealing with various vendors. Our experts will locate the best components for your product.

We offer both SMT and THT assembly, backed by ruggedization options such as conformal coating and potting. Testing includes X-ray, AOI, and ICT. Our processes are 100% ROHS-compliant. The capability exists to assemble 01005 chips, UFBGA/LGA components, and double-sided BGA assembly.

Our quick prototype service lets your R&D team quickly test their designs. You can also use our DFA and DFM services during the design process, helping you finalize designs faster, reduce time to market, and gain a competitive edge.

Prototype Assembly

We provide quick-turn PCB prototype and assembly services for small batches and urgent needs, supporting consignment & turnkey projects.

Production Assembly

Advanced automated equipment allows us to efficiently process production orders without NRE fees, minimum orders, or contractual obligations.

Box Build

Providing box build and electro-mechanical assembly, including PCB integration, cable & wire harnessing, and complete enclosure assembly.

Consigned Assembly

We assemble your circuit boards using advanced automation. You provide all required parts, including the PCBs and electronic components.

Partially Consigned

Supply your custom, stockpiled, and extra parts. We'll help source the rest, including PCBs and missing elements, then assemble your circuit boards.

Turn-key Assembly

We manage the complete process, from sourcing bare PCBs and components to final assembly and testing, ensuring it meets your application needs.

Types of PCBs That We Assemble

We use advanced mounting techniques to assemble three types of PCBs.

- Rigid PCB: This is common in most PCB assemblies. A solid core provides their thickness and rigidity. Fiberglass is a common material, but less expensive options like phenolics or epoxies are available, though they are not as durable.

- Flexible PCB: These offer better bendability compared to rigid boards. High-temperature plastics like Kapton are commonly used, as it blends well.

- Metal Core PCB: This is a good choice for replacing typical FR4 boards. The metal core allows them to spread heat effectively. This helps dissipate heat from the board, protecting heat-sensitive components.

Our PCB Assembly Capabilities

Our factory includes multiple assembly lines. This enables us to meet specific requirements on schedule. We ensure quality by inspecting and testing at each assembly stage. Before production, we identify and resolve any design or production issues in the prototype phase, working with you.

Assembly Types

- SMT

- Thru-hole

- Mixed assembly (SMT & THD)

- Single or double-sided

- Large parts on both sides

- BGA on both sides

- Kit Assembly

Board Types

- FR-4 board

- Metal core board

- Rigid board

- Flexible board

- Rigid-flex board

Component Types

- Passive down to 01005 sizes

- BGA 0.25mm pitch

- Quad flat package no-lead

- Quad flat package (QFP)

- Small Pitch package of 8 mils

- Hard metric connectors

- Cable & Wire

PCB Finish

- SMOBC/HASL

- Electrolytic gold

- Electroless gold

- Electroless silver

- Immersion gold

- Immersion tin

- OSP

Parts Procurement

- Full turnkey

- Partial turnkey

- Kitted/Consigned

Solder Types

- Leaded

- No-clean process

- Lead-free/RoHS compliant

- SMD and TH components assembly

Board Dimensions

- Smallest size: 0.2″ x 0.2″

- Largest size: 24″ x 18″

Quality Inspection

- Visual inspection

- AOI inspection

- X-Ray inspection

- In-circuit test

- Functional test

Quickturn Lead Times

24 Hour Turn

- 10 PCBs Maximum

- Up to 20 BOM Line Items

- Up to 100 SMT placements / board

- Maximum of 10 Through Hole Components per Order

48 Hour Turn

- 30 PCBs Maximum

- Up to 25 BOM Line Items

- Up to 180 SMT placements / board

- Maximum of 50 Through Hole Components per Order

5 Day Turn

- 130 PCBs Maximum

- Up to 50 BOM Line Items

- Up to 600 SMT placements / board

- Maximum of 200 Through Hole Components per Order

7 Day Turn

- 200 PCBs Maximum

- Up to 80 BOM Line Items

- Up to 800 SMT placements / board

- Maximum of 2220 Through Hole Components per Order

Standard Lead Times

7 Day Turn

- 800 PCBs Maximum

- Up to 80 BOM Line Items

- Maximum of 600 Through Hole Components per Order

10 Day Turn

- 1500 PCBs Maximum

- Up to 100 BOM Line Items

- Maximum of 1200 Through Hole Components per Order

15 Day Turn

- 5000 PCBs Maximum

- Up to 130-150 BOM Line Items

- Maximum of 4000 Through Hole Components per Order

20 Day Turn

- 10000 PCBs Maximum

- Up to 200 BOM Line Items

- Maximum of 5000 Through Hole Components per Order

Why Choose Our PCB Assembly Services?

With more than 10 years under our belt in PCB assembly, we’ve got you covered. Our team can help you find replacement components for parts that are out of date or unavailable. Plus, we offer DFX reviews to continuously improve your designs. Choose us, and we’ll make every effort to make sure your assembly is delivered on schedule and meets your quality standards.

We have the capability to assemble critical control system PCBs designed for challenging environments. Our ISO 9001:2015 and UL safety certifications ensure our adherence to rigorous quality and safety standards. For component procurement, we order genuine parts from your designated suppliers or our partner companies.

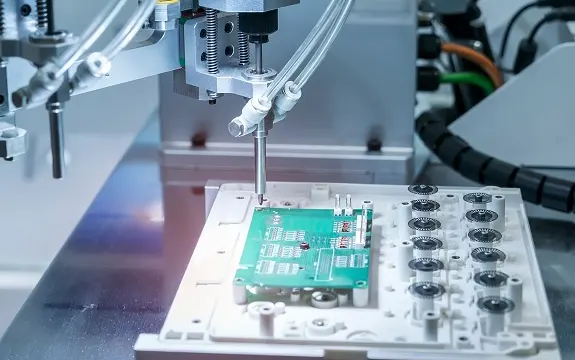

Our PCB Assembly Equipment

We know that to successfully complete PCB design and assembly, the latest software and equipment are key. Our factory in Shenzhen, China, operates eight Panasonic SMT production lines. We consistently invest to better serve our customers. We have the capability to assemble components as small as 01005 passives, QFNs, BGAs, and µBGAs.

Our PCB assembly facility has various workstations and preparation systems. We also have sophisticated soldering systems and a wide range of PCB assembly equipment. This includes testing equipment, pick and place machines, stencil printers, X-ray machines, and automated inspection tools, ensuring we can meet all your assembly needs.