8:00 - 17:30

Monday to Saturday

Monday to Saturday

Comprehensive PCB Solutions from Our Team

Before you begin assembling your printed circuit boards, you need to complete the design and layout process. At PCBAIR, we provide a complete solution—from initial design and layout to fabrication and assembly. We bring expertise in digital, analog, high-speed, and mixed-signal board designs.

If you already have a schematic or drawing but lack the time or tools to finish the design, we’re here to help. After we complete your PCB design and board layout, we manufacture and assemble the board in as little as 48 hours in our own facility. Keeping every process under one roof minimizes delays in file transfers, shipping, and delivery. For over 10 years, we have transformed more than 6,000 CAD drawings into real-world products.

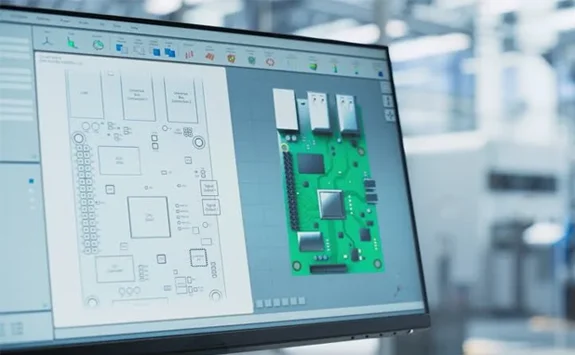

PC Board Layout & Design

We excel in PCB design for high-speed digital, analog, and RF applications. We design single, double, and multi-layer boards using CAD packages. The design process includes schematic capture, parts library creation, high-density component placement, and complex routing. Through signal, power, and thermal integrity analysis, we strive for a first-pass design success.

We follow Design for Manufacturability (DFM) to produce your prototypes and final boards efficiently, and we use Design for Testability (DFT) and Design for Assembly (DFA) to simplify production and cut costs. We also cover your ongoing engineering requirements. We review your Bill of Materials (BoM) to spot high-risk parts and suggest alternatives that reduce obsolescence and compliance risks.

Wireless & RF System Design

PCBAIR designs custom wireless and RF systems, optimizing for range, power consumption, size, or cost tailored to your project’s needs. Our expertise in cellular, Bluetooth, Wi-Fi, Zigbee, and LoRa technologies allows us to create low-power designs that extend battery life and deliver reliable connectivity.

Our RF system design services expedite the launch of your wireless products. We take care of all the important details: system architecture, antenna design, signal integrity, and frequency planning, delivering reliable operation with minimal interference.

Electromagnetic compatibility (EMC) and interference (EMI) mitigation are integral to PCBAIR’s design philosophy. Rather than addressing these as afterthoughts, we integrate effective EMC/EMI solutions into your product from the earliest stages.

Partnering with PCBAIR for your PCB design brings you several advantages, such as:

Delivering On-Time Projects

Your projects remain on schedule, maintaining quality and cost-effectiveness, and ensuring timely PCB design completion.

Simplifying Complex Designs

We expertly handle even the most intricate designs, including those with high-speed signals, mixed-signal components, and precise tolerances, especially those integrating FPGAs.

Ensuring Signal Integrity

We ensure signal clarity and minimize noise and interference, delivering reliable performance in high-speed electronic systems.

Reducing Production Costs

Our designs are optimized for manufacturability from the start, significantly reducing PCB costs across the entire production process.

PCB Design & Layout Process at PCBAIR

Our PCB design and layout process transforms your electronic product concepts into production-ready circuit boards. We follow a comprehensive process, ensuring quality and efficiency at every step:

Schematic Capture

We create detailed schematic diagrams from your design ideas using electronic design automation (EDA) tools. These diagrams serve as a precise blueprint for all electrical connections, components, and the BOM.

PCB Component Footprint Creation

Accurate footprints are essential for precise component placement and manufacturability. Our designers select the optimal mounting technology (SMT or THT) and determine the required number of layers (from single to 30-layer designs) based on your project’s specifications. Component placement also takes Design for Manufacturing (DFM) principles into consideration.

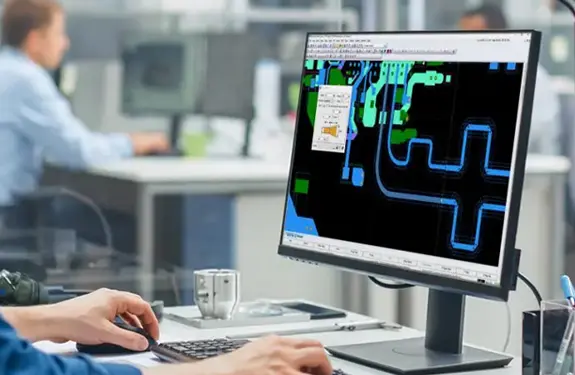

PCB Routing

After component placement, we route the physical connections between them. Using the schematic’s netlist and specialized PCB software, our designers ensure efficient signal flow, minimize interference, and maximize performance. We use simulations to proactively identify and resolve potential routing issues, even in complex layouts.

PCB Verification and Analysis

We rigorously verify the PCB design to ensure it meets all specifications, adheres to IPC standards, and achieves EMC compliance, making it ready for manufacturing. This includes:

- Design Rule Checks (DRC): Ensuring the layout adheres to manufacturing constraints.

- Layout Versus Schematic (LVS): Confirming the physical layout matches the schematic connections.

- Signal Integrity Analysis: Evaluating the design for potential signal problems.

For designs incorporating ASICs or FPGAs, we also adhere to relevant design and testing guidelines.

Output – Manufacturing Files

The final step is generating the complete set of manufacturing files, including Gerber files and drill files, ready for PCB fabrication.

Your PCB Designing Experts

PCBAIR typically starts by analyzing your product concept. We work with you to understand your technical needs and priorities, allowing our engineers to develop the best design solutions for your hardware. The PCB design phase is critical, and we refine the design through multiple iterations and assessments to ensure optimal results.

With over a decade of experience, PCBAIR’s hardware design engineers ensure all products meet international quality standards and exceed expectations. We provide reliable support to businesses of all sizes, from small local companies to large international organizations.