8:00 - 17:30

Monday to Saturday

Monday to Saturday

ABOUT PCBAIR

PCBAIR, a PCB/PCBA/EMS provider based in Shenzhen, China, has been delivering fully turnkey manufacturing solutions since 2014. Our operations include PCB design, fabrication, parts sourcing, assembly, and quality control.

We also offer IC chip programming, case assembly, functionality testing, and box building. Every PCB we produce meets rigorous quality standards, encompassing Rigid PCB, Flex PCB, and Rigid-Flex PCB types. We adhere to ISO 9001:2015, ISO 13485:2016, J-STD-001, IPC-A-610E, IATF16949, and UL-ZPMV8.E522850 certifications to ensure product reliability.

We Design and Manufacture

PCB & SMT, you need a faster factory while maintaining high quality and reliability.

Our team designs printed circuit boards tailored to your needs, including rigid, flexible, multilayer, HDI boards, and high-speed PCBs. At PCBAIR, our designers can start from scratch or refine your existing electric circuit design. We create prototypes, develop embedded software, test products, and prepare all necessary design and layout documentation.

At PCBAIR, we specialize in creating analog, digital, and mixed-signal boards for bespoke electronics. We offer consultations, evaluate your projects, and handle every stage of development—from schematics and layout to testing and validation. Our processes utilize design for manufacturability (DFMA) principles, and we can assist with certification and production launch.

Prototype PCBs provide an essential step in confirming your design is accurate before launching into mass production, helping you steer clear of expensive mistakes. The sooner you receive the prototype circuit board, the quicker you can proceed with testing and move into standard production.

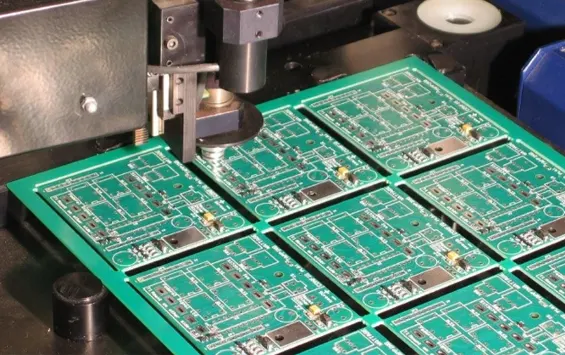

As a reliable PCB prototype manufacturer, we support your design iterations with our tailored PCB prototype services. Our expedited prototype service can deliver results in as little as 24 hours without compromising on quality. Our team uses advanced equipment and techniques like laser direct imaging, vision drilling, and inkjet printing to produce high quality prototype circuit boards for you.

Our custom PCB fabrication services can handle both simple and complex PCB projects. We can meet your specific needs, no matter the layer count, materials, densities, processes, and finishes required for your PCBs.

PCBAIR provides high-quality, affordable PCB manufacturing services. Our PCBs feature soldermask over bare copper (SMOBC) and a hot air solder leveling (HASL) finish, complete with flying probe testing (FPT). You can tailor your PCBs to meet specific requirements through our customization service. We can provide support from prototyping to mass production.

We offer a diverse selection of PCBs that comply with RoHS standards, catering to various needs such as high-frequency and high-temperature applications. We can manufacture rigid PCBs, flexible PCBs, rigid-flex PCBs, aluminum-backed PCBs, and metal-core PCBs. For more specialized requirements, we also produce Advanced PCBs such as Heavy Copper PCBs, Hybrid RF PCBs, and Ceramic PCBs. Moreover, we offer PCBs in standard shapes like rectangles and circles, as well as unique, custom-specified geometries to fit specific assembly requirements.

From prototyping to mass production, PCBAIR offers the services you need, supporting your project at every stage. We use advanced SMT and THT technology to produce high-quality and dependable products swiftly for our clients.

With our expertise in electrical and mechanical engineering, we provide comprehensive PCBA solutions. These include design for assembly (DFA) checks, PCB manufacturing, component sourcing, and more. We also offer services like SMT, DIP, PCBA testing, IC programming, conformal coating, electronic potting adhesive, enclosure creation, and final product assembly. This ensures that you receive a customized electro-mechanical solution that meets your specific needs.

Factory Scale

We have two factories in Shenzhen, measuring about 15,000 square meters, equipped with professional equipment, an engineering team, and a quality control team.

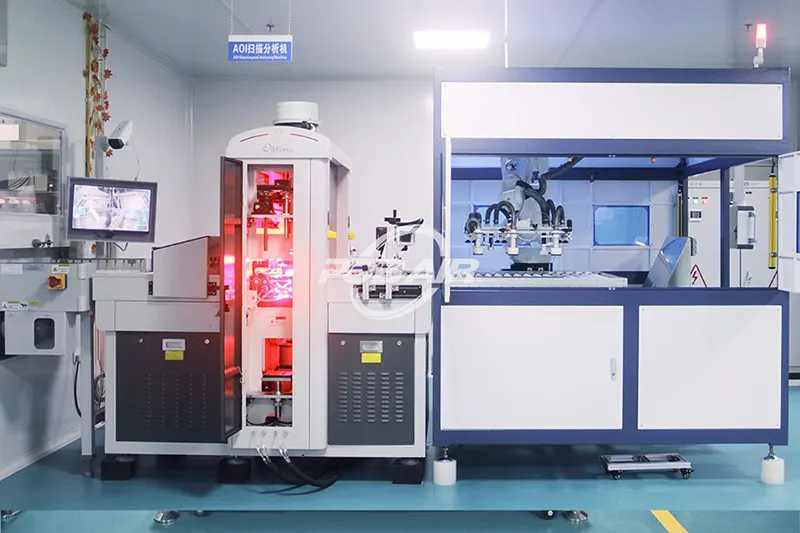

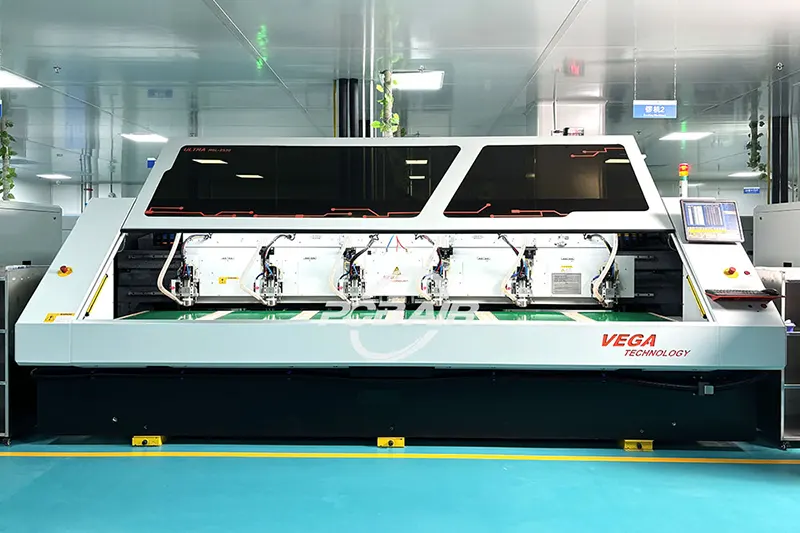

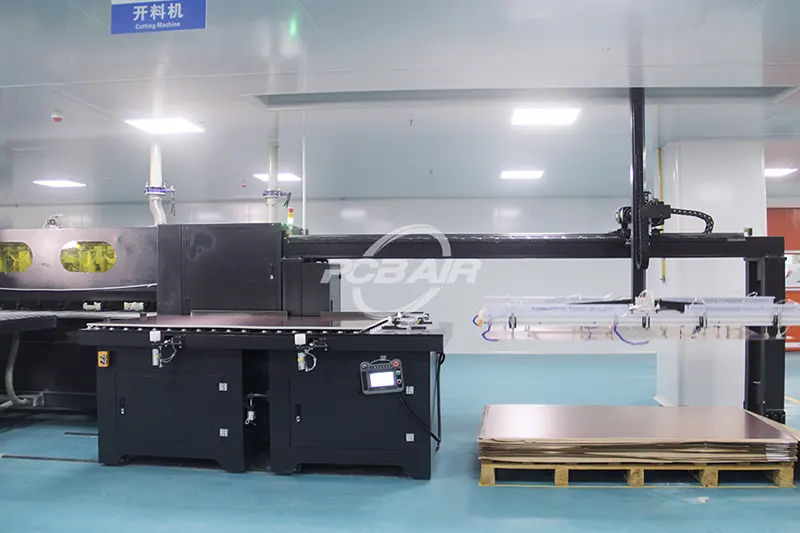

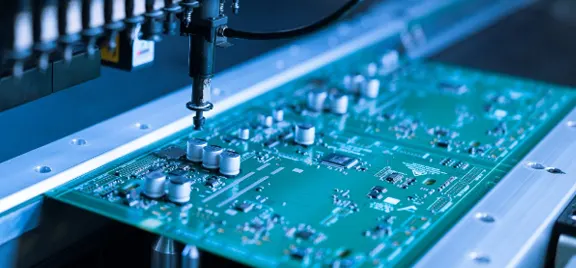

Advanced PCB Equipment

We use computer-guided and automated machinery to ensure accuracy and efficiency in the PCB manufacturing and assembly process. We also perform numerous quality checks to guarantee that the PCBs delivered to our customers meet high-quality standards.

Certifications & Standards

Our factory prioritizes efficiency and quality control. Through rigorous DFM (Design for Manufacturability) inspection, IQC (Incoming Quality Control), IPQC (In-Process Quality Control), and OQA (Outgoing Quality Assurance) processes, we ensure products meet high-quality standards.

We’ve earned key certifications, including ISO 9001:2015 for quality management systems, ISO 13485 for medical devices, IATF 16949 for automotive quality management, SGS certification, UL certification, and more. Our PCBs meet IPC-A-600 Class 2 standards, with Class 3 for medical and automotive and Class 3A for aerospace applications. We strive to provide the reliable products and services you expect.

Our Teams

Everybody working together as a cohesive unit.