8:00 - 17:30

Monday to Saturday

Monday to Saturday

Technical Capabilities

From intricate multi-layer boards and HDI to specialized materials and full assembly, we have the technology and know-how to deliver prototypes accurately to your specifications.

Quality

Control

Our rigorous quality control, adhering to IPC standards, ensures every board is precisely manufactured and assembled correctly, ready for dependable testing and validation.

Turnaround

Time

We offer rapid PCB prototype manufacturing and assembly, with options starting from 24 hours, getting functional boards into your hands quickly when your project demands them.

Competitive Pricing

Our in-house factory enables us to provide competitive rates for design, manufacturing, and assembly, helping you manage your budget effectively without surprises.

Prototype PCB Design

Transform your schematics or concepts into production-ready PCBs. Our expert engineers deliver high-performance, cost-effective, and reliable PCB layouts. We master the complexities of signal integrity, power delivery, and thermal performance, especially for demanding high-speed, RF, and HDI designs. By embedding DFM and DFA principles from the start, we proactively minimize production issues and eliminate costly revisions. You receive validated Gerber files and comprehensive documentation, perfectly prepared for direct fabrication handoff and ensuring first-pass manufacturing success.

Prototype PCB Fabrication

Our PCB prototyping service delivers accurately manufactured boards with rapid turnaround times. Production adheres to IPC-A-600 Class 2 standards (Class 3 available upon request), achieving high quality through rigorous process control.

You can select from RoHS-compliant materials, including FR-4, Rogers, flexible substrates, and aluminum, available with surface finishes like lead-free HASL, ENIG, and OSP. We manufacture prototypes up to 20 layers, featuring fine lines down to 3/3 mil produced with Laser Direct Imaging (LDI). To confirm conformance to your design specifications, every board undergoes AOI and 100% E-Test.

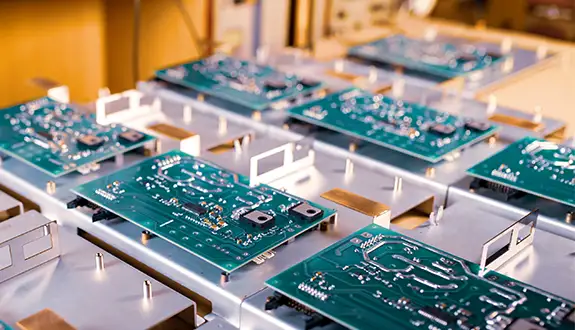

Quick Turnkey PCB Assembly

PCBAIR offers turnkey PCB assembly services, streamlining the entire process from design to delivery. Our capabilities include double-sided and mixed technology (Surface Mount / Through-Hole) assembly, reflow and wave soldering, placement of components down to 01005 imperial (0402 metric) size, and handling of 0.25mm pitch BGAs and other fine-pitch parts. Board assembly can often be completed within 24 hours once all components are available.

For quality assurance, detailed visual inspection is standard, with X-ray inspection also available to confirm solder integrity and accurate component placement. We conduct detailed tracking for each prototype project, documenting the source of every component and all assembly steps. You receive functional prototypes prepared for immediate testing, supporting faster validation and reduced time-to-market.

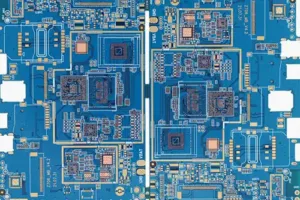

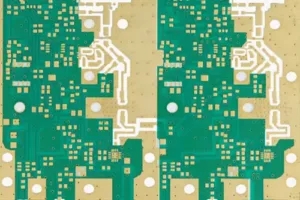

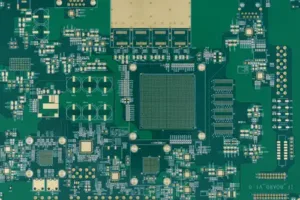

Example Prototype PCBs Manufactured by Us:

Our manufacturing capabilities include both simple double-sided and complex multi-layer PCBs. We produce bare boards using diverse materials including Grace FR406, ISOLA FR408, Arlon, Nelco, Metal Core, and many others.

8-layer PCB (1.2mm, Isola Halogen-free FR-4) with blue solder mask, white silkscreen, and ENIG finish.

4-layer Hybrid PCB (1.2mm, Rogers 4350B + FR4) with green solder mask, white silkscreen, and ENIG finish.

8-layer PCB (2.0mm, High Tg FR4) with green solder mask, white silkscreen, ENIG finish, and ±7% impedance control.

2-layer Ceramic PCB (1.6mm, 99.5% Al2O3) with white solder mask, no silkscreen, and ENIG finish.

2-layer Rigid-flex PCB (1.0mm, FR4+PI) with red solder mask, white silkscreen, and ENIG finish.

Fast Prototype PCB Turnarounds

Our standard manufacturing lead time for prototype PCBs, produced at our facility in China, is typically 10 business days. Lead times can vary depending on the complexity of your boards and the quantity ordered. For projects requiring faster completion, we offer fast turnaround options, including 24-hour, 2-day, 3-day, 5-day, and 7-day.

The 24-hour turnaround is generally available for single and two-layer prototype boards. For multi-layer PCBs, the fastest possible manufacturing time is determined by factors such as the layer count and order quantity. Please submit your Gerber files through our online quote form and we will include the available manufacturing lead times in our quote. We can provide shipping estimates upon request.