Monday to Sunday

What Do We Offer?

From design to volume production, we are your experts in turning printed circuit board ideas into reality. We offer fast turnaround times and competitive pricing.

We offer a variety of PCB design and layout services for your prototype and production projects.

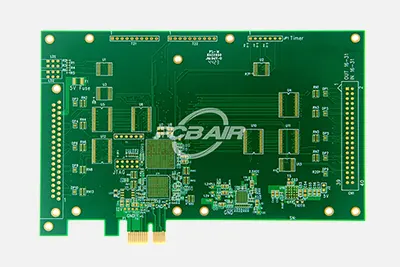

PCB Prototype

We provide quick prototyping services and reverse engineering of existing components.

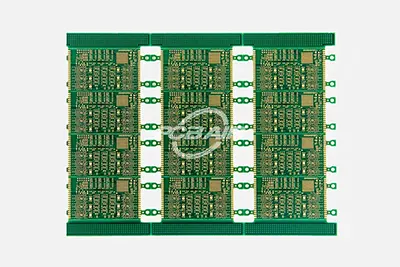

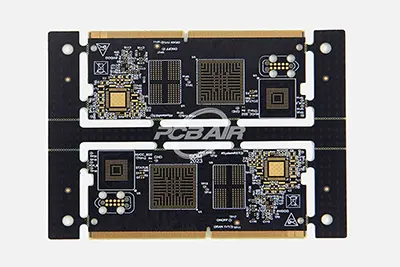

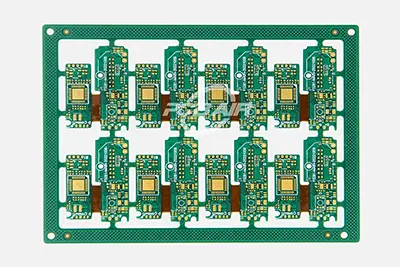

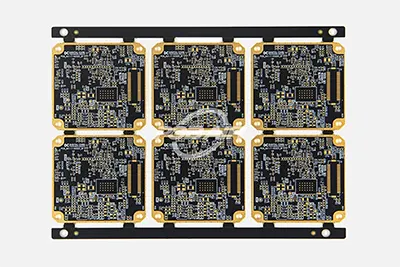

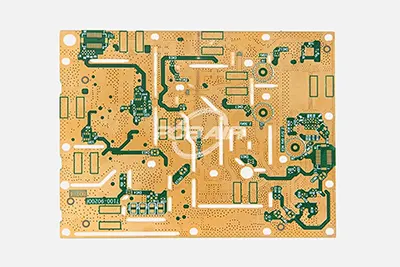

PCB Fabrication

We meet your PCB manufacturing needs, specifically for high-complexity and special material PCBs.

PCB Assembly

We offer reliable consignment, full turnkey, and partial turnkey assembly services.

Welcome to PCBAIR !

We are a trusted Chinese manufacturer of printed circuit boards and provider of quick-turn PCB assembly solutions. We offer custom PCBs of all types, from prototyping to component sourcing, stencil creation, assembly, and testing. We support highly specialized precision PCBs and production from small batches to large scale.

Our engineering team collaborates closely with you during the initial design and development stages to ensure your product is consistently high-quality and manufacturable. Learn More…

ADVANTAGES

Material Assured

We use high-grade fr-4, rogers, and aluminum materials in our PCB production to ensure high quality.

Technical Support

During your PCB design and manufacturing process, our technical experts will offer advice and support.

High Reliability

With over 10 years of fabrication experience, we guarantee quality. If issues arise, we’ll remake your PCBs for free.

One-Stop Service

Our PCB manufacturing and assembly are completed in the same facility, leveraging a global supply chain for efficient parts sourcing.

On Time Delivery

We offer expedited PCB production and delivery, getting your boards to you in as little as 3-4 business days.

High-Quality PCB

Our high-quality PCBs are utilized in fields such as communications, industrial control, computer applications, medical, and test equipment. We are certified to ISO9001, ISO14001, TS16949, UL and RoHS standards.

Satisfactory Service

Our emphasis is on service. You’ll experience this when we work together. We focus on market trends, by maintaining a full stock of standard parts, ensuring rapid delivery times.

● Quick 2-hour response, quote in 12 hours.

● Transparent order tracking from first day to final delivery.

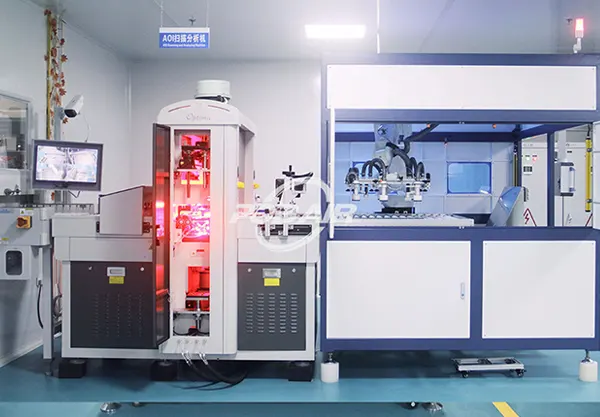

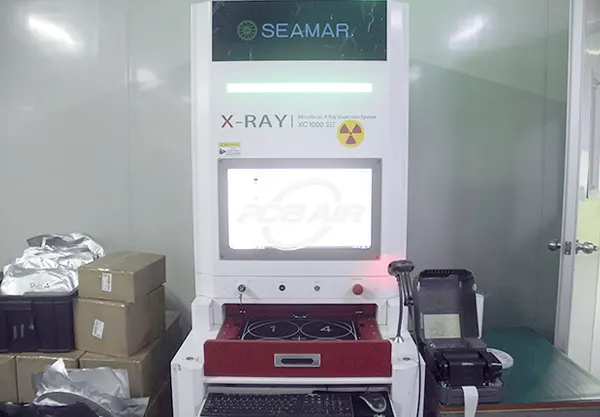

PCB Manufacturing Equipment

PCBAIR uses the latest technology and automated machines to produce your PCBs with precision and efficiency. We carefully select our manufacturing and testing equipment to ensure each board meets high quality standards and moves smoothly through production.

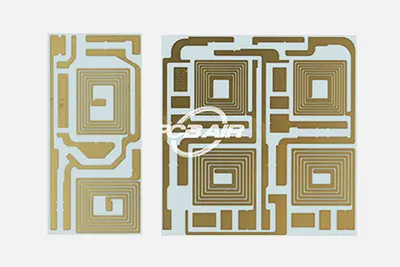

Our technical capabilities include 4-48 layer PCBs, HDI, Heavy Copper boards, Rigid-Flex, Flex (FPC), AL-base PCBs, Ceramic PCBs, RF Microwave boards, and Metal Core PCBs.

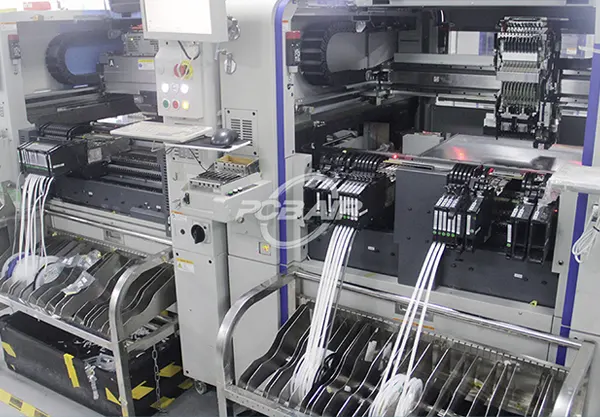

PCB Assembly Equipment

The PCB assembly process is complex and involves multiple aspects. It requires a multitude of tools and equipment, such as solder paste printing machines, SPI machines, glue dispensing machines, pick-and-place machines, reflow soldering machines, wave soldering machines, AOI machines, ICT fixtures, and FVT fixtures.

PCBAIR invests in purchasing advanced equipment necessary to achieve the required precision throughout the entire PCB assembly process. This allows us to deliver high-quality PCBs at competitive prices.